CNC milling - what does this machining method allow?

Propart

The precision and accuracy of CNC turning are the result of advanced computer control technology, modern drive systems, stable machine design, advanced sensors, and proper calibration and maintenance. Thanks to these factors, CNC turning is able to meet the requirements of the most demanding industrial applications, ensuring high quality and repeatability of manufactured elements. The CNC turning process is an integral part of modern industrial production, enabling the production of complex elements in an efficient and reliable manner.

Here are the main advantages of CNC milling:

01

High precision and accuracy

CNC milling allows for very precise dimensional tolerances, which is crucial for the production of precision parts.

02

Repeatability

Thanks to computer programming, each part can be made identically, which is important for mass production.

03

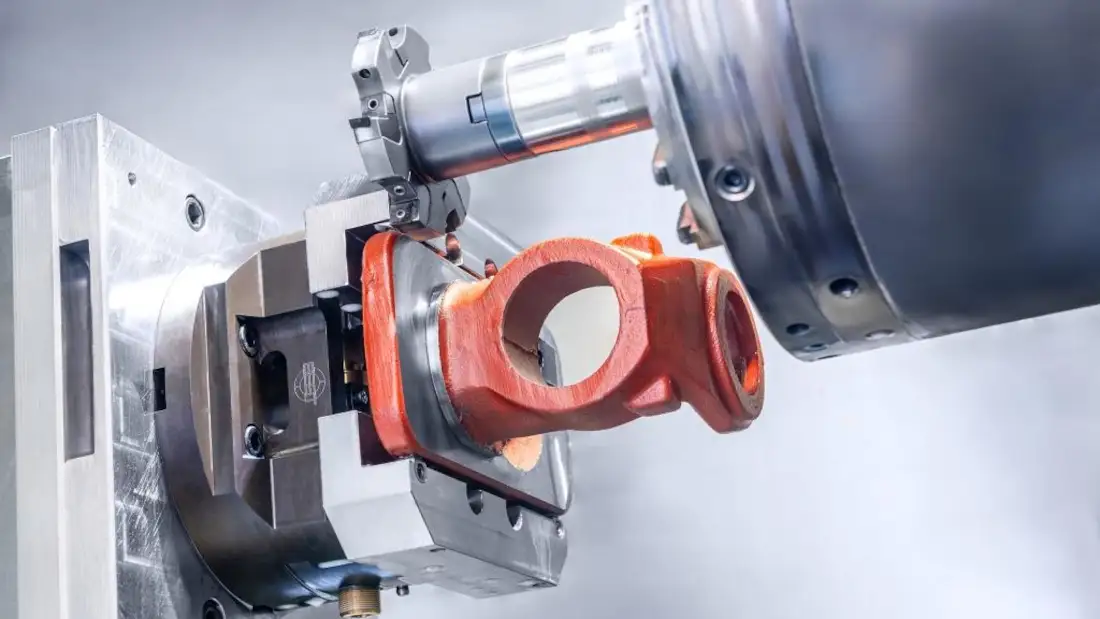

Complex geometries

CNC milling allows the creation of complex shapes and patterns that would be difficult or impossible to achieve using traditional machining methods.

04

Wide range of materials

Ability to process a variety of materials such as metals (steel, aluminum, titanium), plastics, wood, composites, and more.

05

Production efficiency

Automation of the process allows for fast and efficient production of parts, which reduces production time and costs.

06

Waste reduction

Precise control of the cutting process minimizes material waste, which is both economically and ecologically beneficial.

07

Production flexibility

Ease of changing CNC programs allows for quick adaptation of the production process to different designs and specifications without having to change machines.

08

Ability to implement complex projects

CNC milling allows for the implementation of complex projects that require multi-axis machining and precise cutting.

CNC milling process step by step

- Design: Creation of a digital model of the part in CAD software.

- Programming: Converting the CAD model to G-code instructions using CAM software.

- Machine setup: Mounting the workpiece on the CNC milling table and installing the appropriate cutting tools.

- Machining: A CNC milling machine executes program instructions by making precise movements of the cutting tool to remove material and shape the part as designed.

- Quality control: Inspecting the finished part to ensure that it meets design requirements and dimensional tolerances.

Precision and accuracy of CNC milling are key aspects of this machining technology. Here are the details about these features:

01

Machine stability

CNC milling machines are designed with high-quality components and materials that provide stability and minimize vibration, which contributes to precise operation.

02

Control technology

Modern CNC systems use advanced control technologies that monitor and correct the machine’s movements in real time, ensuring precise and accurate execution of the program.

03

Calibration and maintenance

Regular calibration and maintenance of the machine are essential to maintaining its accuracy. An improperly calibrated machine can lead to machining errors.

04

Tool accuracy

Cutting tools must be precisely balanced and sharpened to ensure accurate machining. Any wear or damage to tools can affect accuracy.

05

Dimensional Tolerances

CNC milling machines can handle dimensions with very tight tolerances. Typical tolerances are ±0.01 mm to ±0.1 mm, but with advanced machinery and technology, they can be even tighter.

06

Part Geometry

The accuracy of CNC milling allows for the precise production of complex geometry, such as differently shaped holes, contours, and cutouts that must meet design specifications.

07

Program Adjustments

CNC systems can include adjustments in the machining program to compensate for possible errors due to tool tolerances or changing machining conditions.

08

Measurement and Control

Modern CNC machines can be equipped with measurement systems, such as sensors and probes, that monitor and regulate the machining process in real time, ensuring high dimensional accuracy.

The precision and accuracy of CNC milling make it an extremely versatile and reliable technology, especially in production requiring high quality and tight tolerances.