CNC Services

CNC Turning

CNC Milling

Service from A to Z

Comprehensive

Customer service

We have extensive experience in the industry, and our services are trusted by Customers, among others: from Europe and the United States.

CNC

Machining

We offer a comlex product manufacturing process, which we effectively select depending on the specific requirements of our Customers.

Measurement services

Laboratory

We have advanced measuring machines that guarantee repeatability and precision of the results obtained.

0

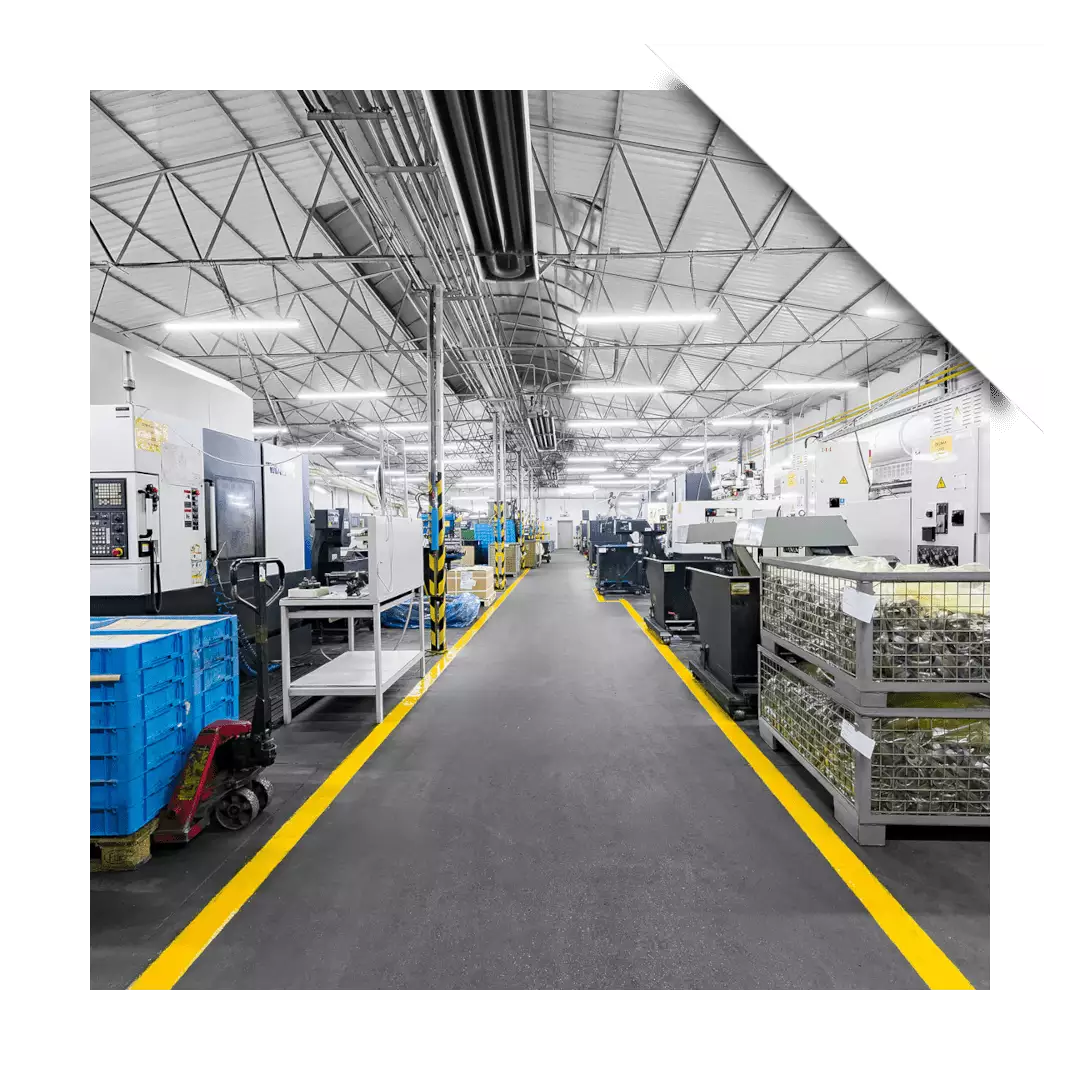

More than 100 machines

0

About 340 Details

0

Over 30 years of experience in the industry

Why

Us?

The competence and experience of the crew as well as modern equipment mean that our capabilities are constantly growing.

Professional CNC Services Propart sp. z o.o.

CNC technology has revolutionized the manufacturing industry. With computer numerical control, machines can perform precise and complex tasks with unprecedented accuracy and efficiency. This has led to significant increases in productivity and quality across various industries, from automotive to aerospace and astronautics. Propart Sp. z o.o. specializes in CNC metal machining. This technology allows for precise and efficient processing of metals, enabling the creation of intricate shapes and details with high accuracy. CNC machining is a key process in the production of components for various sectors, including machinery, automotive, and aerospace, as well as other industries requiring high precision and quality. We work with cast

CNC technology has revolutionized the manufacturing industry. With computer numerical control, machines can perform precise and complex tasks with unprecedented accuracy and efficiency. This has led to significant increases in productivity and quality across various industries, from automotive to aerospace and astronautics. Propart Sp. z o.o. specializes in CNC metal machining. This technology allows for precise and efficient processing of metals, enabling the creation of intricate shapes and details with high accuracy. CNC machining is a key process in the production of components for various sectors, including machinery, automotive, and aerospace, as well as other industries requiring high precision and quality. We work with cast iron, steel, aluminium, and non-ferrous metals.

Why Choose Propart Sp. z o.o.?

We take pride in:

- High Product Quality dOur advanced CNC machines deliver components that meet rigorous quality standards.

- International Reputation: Propart is valued in the international market, reflecting the trust of long-term clients from various countries.

- Employee Engagement: We care for our employees, which translates into high-quality work and team commitment.

Thanks to investments in modern technologies and continuous development, we maintain high production standards and can meet the growing demands of the market.

Description of CNC Metal Machining Technology:

- 3-Axis Milling: Machining flat surfaces and 3D shapes using three axes of movement (X, Y, Z).

- 5-Axis Milling: Allows for machining complex shapes and details with greater precision, thanks to two additional rotary axes (A, B), enabling simultaneous machining of multiple surfaces for increased efficiency.

- CNC Turning: Rotating the material around its axis and removing excess material with cutting tools. Ideal for producing cylindrical components such as shafts, sleeves, rings, and threads.

- CNC Threading: Creating precise internal and external threads on various parts using specialized threading tools, ensuring high quality and compliance with international standards.

- CNC Grinding: Precision finishing of surfaces using grinding wheels or tools, allowing for very smooth surfaces and high dimensional accuracy, essential in advanced industrial applications.

- CNC Boring: Enlarging existing holes to achieve precise dimensions and surface smoothness, crucial for producing components that require precise holes, such as bearings and sockets.

By utilizing these advanced technologies, we ensure high quality and precision in the production of metal components. Our attention to detail and the use of modern CNC machining methods allow us to meet the demands of clients from various industries and maintain high production standards.

Measuring Laboratory

Specializing in precise CNC metal machining, we have well-equipped measuring laboratories. Such facilities are essential for ensuring the highest quality and precision in component production. Our measuring lab includes:

- CMM (Coordinate Measuring Machines):Facilitating precise three-dimensional measurements of complex shapes and details to verify product compliance with technical requirements.

- Optical Measurement Systems: Used for non-contact measurement of dimensions and shapes, ideal for delicate or hard-to-measure components.

- Profilometers: Employed to measure surface roughness and contours, which is vital for ensuring high-quality surface finishes.

- Hardness Testers: Used to determine material hardness, crucial for ensuring the appropriate mechanical properties of components.

- Image Analysis Systems: Allow for detailed analysis of shapes and dimensions using advanced visual technologies.

- Other specialized measuring tools:Callipers, micrometres, height gauges, protractors, and other precision instruments used in advanced control processes.

Having such an advanced measuring laboratory allows us to monitor every stage of production, from raw materials to finished products, ensuring the highest quality and compliance with client requirements. This helps maintain our international reputation and trust in the industry.

Comprehensive Service and CNC Solutions

Propart offers comprehensive customer service, addressing all needs, including those not directly fulfilled in our facility. In collaboration with our long-term trusted partners, we can offer:

- Zinc plating

- Heat and chemical treatment (including hardening, nitriding, carburizing)

- Anodizing

- Bluing

- Phosphate coating

- KTL painting

We kindly invite you to contact us for any further clarifications.

Read more ...

Milling,

Turning

Turning

milling in 3-, 4-

and 5-axis,

turning

and 5-axis,

turning

Machining

machining of steel forgings, iron, steel and magnesium castings, round, square and flat bars and seamless precision tubes

Materials

gray cast iron, ductile iron, cast steel, black steel, alloy steel and acid-resistant steel, aluminum and brass

Complementary

services

services

powder coating, assembly, washing, special packaging